Twenty years ago, before everything went digital, paper was more of a consideration than it is today. Technology has completely flipped the way businesses consider their paper products and what paper products that they decide are necessary.

Paper, read all about it!

Back then, Business cards and stationery were usually one or two colors. This was due to the cost and technology at the time. Because of this lack of different colored ink on the piece, it made the paper itself one of the most important design elements.

Today, though, because of technological advancements, most print jobs are very similar. Business cards are often gang run because they are all full color and the choice of paper stocks are typically one of four types: coated or uncoated, thick or extra thick. That’s it.

The ability to print full color more efficiently and at a lower price point has given designers more freedom. This gave paper quality less importance in a final piece.

The advancements have also changed the general business owner as well. More and more cost conscious people are using their ink jet and laser printers to print stationery and envelopes. The technology boom has allowed businesses to own color printers of their own.

But this doesn’t mean that you don’t have any access to paper that can make your printed materials look more awesome.

Digital Printing Press

Paper still matters

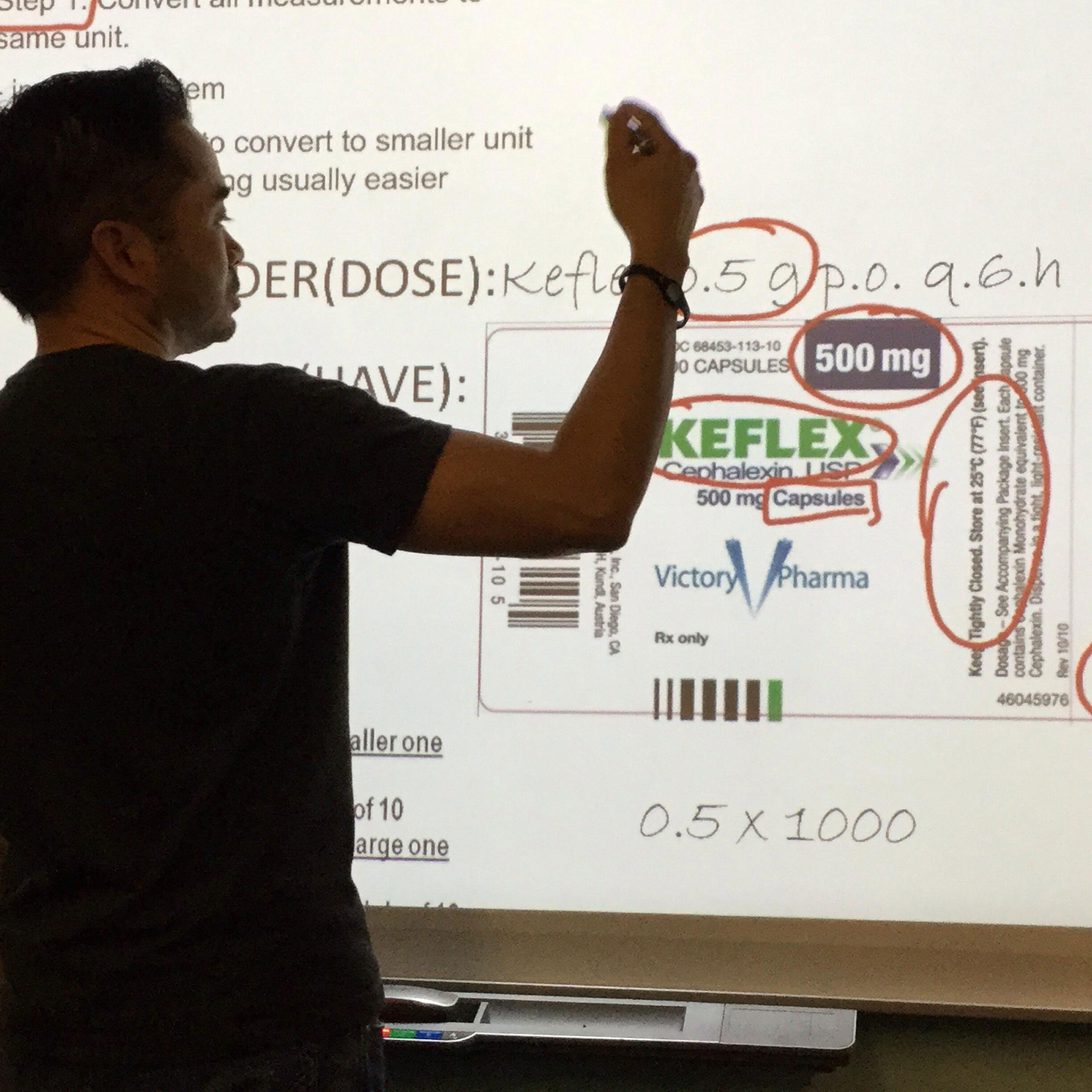

The quality and presentation of a certain paper type on a printed piece can totally change the perception of a viewer. Which may be exactly what you need.

So What Do I Need to Know?

If you you would like to consider a nicer paper with a texture you’ll have to run your job separately, which will probably double your cost. The issues you might run into are numerous.

If you choose a type of paper that the printer usually keeps in stock, you should ask if when it comes time to re-order, will there be any problems finding this paper again? There are a lot of paper types that can become discontinued. Talk to your printer about using a sheet that is readily available.

They may have a new unique sheet in stock that may not be available next time you want to run it. It may make your job really stand out now but you’ll be looking for a replacement later.

If you’re printing in full color, the major consideration is the whiteness and texture of the sheet. The sub-strait, which some printers refer to as paper, can change the look of the colors from piece to piece. These are typically graded as No.1, No.2 and No.3 sheets. The No 1 sheet being the whitest, highest quality and usually most expensive.

You have to be on top of this, though. Different paper companies might have different standards. It’s often hard to see the difference. If you have a lot of ink coverage you may have to sit back and consider the additional cost. My best suggestion is to request paper samples before you try to make a decision.

Especially if your printing a lot of different elements that should look consistent between one piece and another. A good example would be a package with a full color instruction sheet. When you put the two next to each other, there could be a considerable color change between the two pieces if you’re not careful.

The other things you need to consider is if you want to have a coated sheet or an un-coated sheet. In full color printing, a coated sheet is best. The color isn’t absorbed into the sheet as much as a non coated sheet. Printers will refer to these as C1s or C2s because the paper is available coated on one side, C1s, or 2 sides, C2s.

Paper Thickness

The next consideration you need to make is the thickness of the paper. Text weight is the thinnest and can range from 20 lb to 100 lb. It is used for stationery, brochures, flyers, books and magazines, and colored copies.

Cover weight is much thicker and used for business cards, brochures, postcards, presentation folders, and packages. Those are also rated in lbs from 50lb to 110 lbs. Another rate of measurement sometimes used and usually used to refer to the heavier weights is pts. Heavier stocks are used for packaging and usually go from 12 pts. and up.

Coatings

The last thing to consider is coatings. A varnish is a coating added while the job is being printed. It protects the job from finger prints and adds a little vibrancy to the job. An aquias coating is a water based coating which is friendlier to the environment. A UV coating makes your printed piece very shiny but very prone to fingerprints. All of these coatings can be spot coated adding another element to your job. All of these coatings are also available in a dull finish which makes the color look richer without shininess or finger prints.

Paper, like most things in the graphics and marketing industry, is deceptively complicated. If you need assistance with your design or your printing, call us up at 954-680-4584 and we can help you through the complications to what you need.